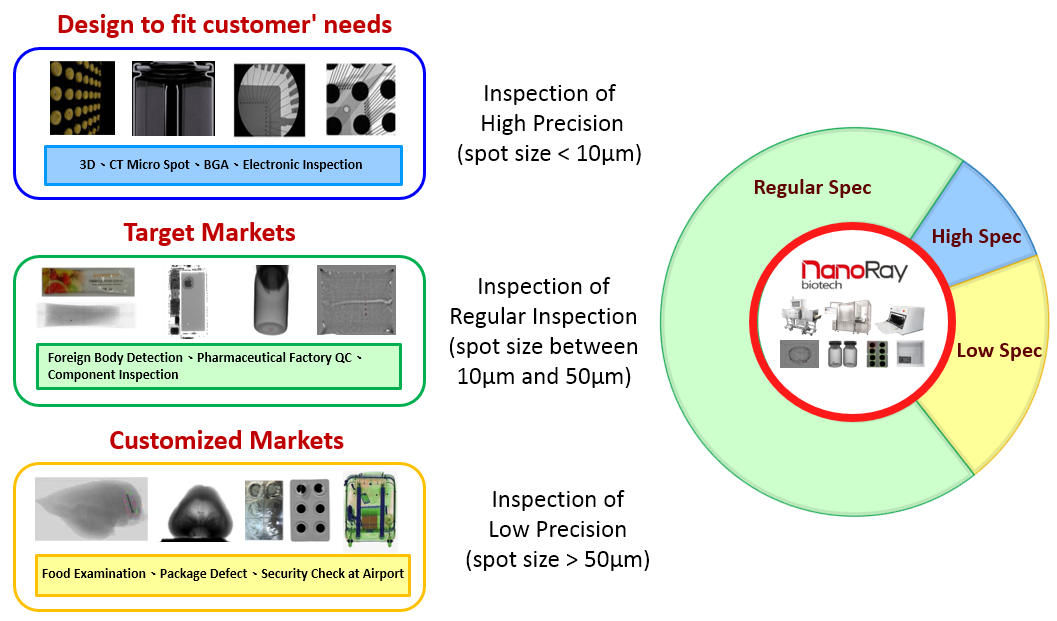

Non-destructive Inspection Equipment

Recently, the development of Industry 4.0 manufacturing has led to the adoption of some technologies, such as automation, precisely-controlled intelligent procedures and high-performance high-efficiency quality control. Currently, there are two types of automatic inspections in non-destructive test: Automation Optical Inspection (AOI), which is applied in the product appearance examination and variance analysis, and Automation X-ray Inspection (AXI), which conducts non-destructive test, such as quality control, detection of foreign object and structural analysis, by density difference on images.

AXI is one of the preferred non-destructive test methods. It can inspect samples by detection of the digitalized image features (such as material, density and thickness) taken by the inspection machines without destructing the samples and their appearances. In the production line, X-ray inspection systems can control quality automatically and intelligently by checking the completeness of the packages and the detection of foreign objects, defects and partial filling.